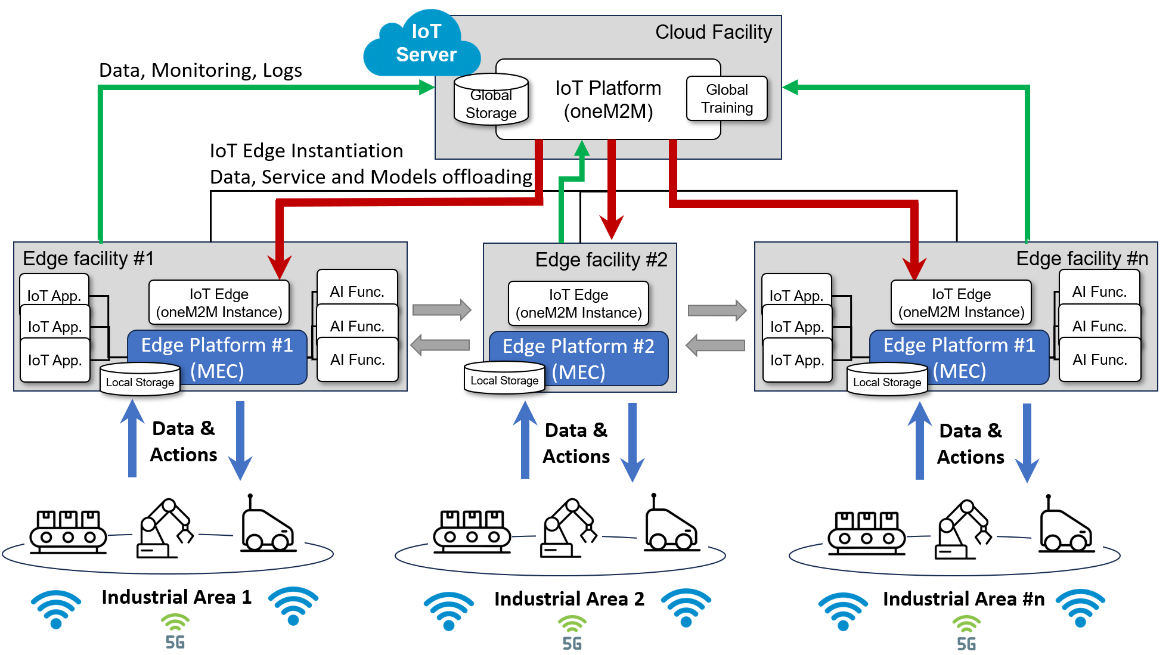

This clause illustrates the integration of oneM2M’s IoT platform with the ETSI MEC edge computing framework to support Industrial Digital Twins (IDTs) in smart manufacturing environments. The architecture enables continuous monitoring, predictive analytics, and autonomous decision-making by synchronizing digital representations of physical assets across both cloud and edge infrastructures.

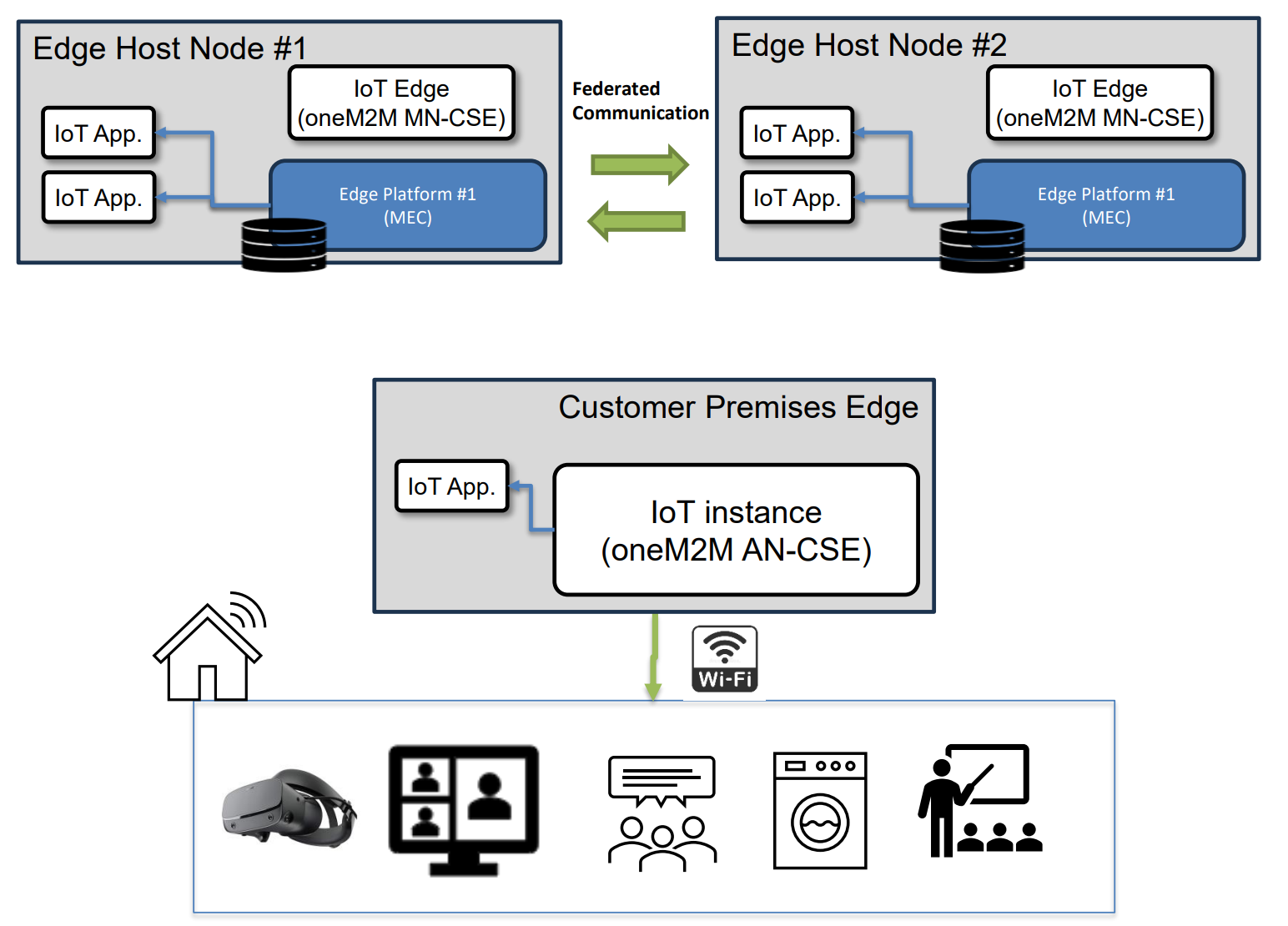

The system design is centered on a cloud-based oneM2M IN-CSE (Infrastructure Node Common Service Entity), which serves as a centralized orchestrator and master digital repository. It is complemented by multiple MN-CSEs (Middle Node CSEs) deployed on MEC nodes located close to industrial machinery or production units. These MN-CSEs perform ultra-low-latency processing of time-sensitive data streams, including sensor readings, robotic operations, energy usage, and environmental parameters.

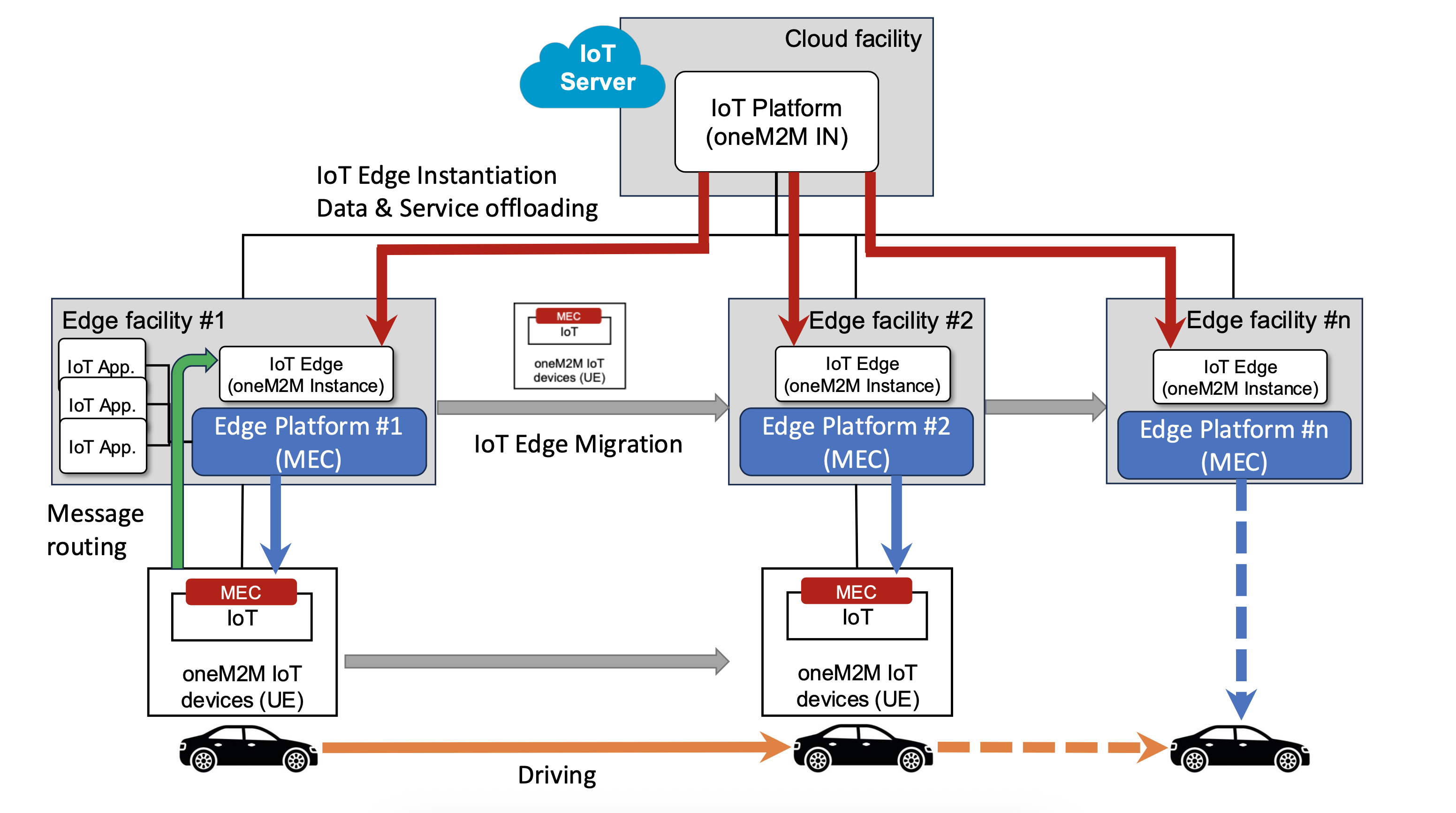

By executing local analytics—such as anomaly detection, real-time quality control, and safety checks—at the edge, the MN-CSEs enable immediate responses and reduce reliance on distant cloud resources. When physical assets transition between operational zones, the system maintains digital twin continuity by dynamically migrating application states and data between MEC nodes. The IN-CSE coordinates this handover while ensuring consistent synchronization across the cloud-edge continuum.

Initially, the IN-CSE hosts the master models of assets such as CNC machines, collaborative robots (cobots), or AGVs, maintaining historical records, operational parameters, and contextual metadata. When a local task is initiated in a particular factory cell covered by a MEC node, the IN-CSE delegates computational responsibilities to the corresponding edge-hosted MN-CSE. This node ingests live telemetry data—including vibrations, temperature, system workload, and fault logs—and performs critical analytics for yield optimization and predictive maintenance.

The MN-CSE may also interact with AI-based MEC applications, such as visual inspection tools or motion controllers, leveraging MEC’s API ecosystem to support advanced automation. As mobile units like AGVs move across zones, the MEC platform uses Application Mobility Services to migrate workloads to the next MN-CSE while preserving real-time functionality. This ensures that no service interruptions occur during asset movement, and digital twin accuracy is maintained.

Throughout this process, oneM2M’s standardized resource and data models ensure interoperability across heterogeneous systems. The result is a robust framework for real-time control, cloud-scale analytics, and adaptive manufacturing operations.

Empowering predictive, adaptive, and autonomous control in smart factories through synchronized cloud-edge digital twins.

The founding members of this initiative are CNIT, UNIMORE, xFlow, JK Consulting and Projects, FSCOM, Sejong University, Digital SME, Deutsche Telekom AG, Exacta GSS, Networks SRL, and Telecom Italia S.p.A. To register or learn more, contact estimed@etsi.org or visit https://estimed.etsi.org.

About ETSI

ETSI provides members with an open and inclusive environment to support the development, ratification, and testing of globally applicable standards for ICT systems and services across all sectors of industry and society. We are a non-profit body with more than 950 member organizations worldwide, drawn from 64 countries and five continents. Our members include large and small private companies, research entities, academia, government, and public organizations. ETSI is officially recognized by the EU as a European Standardization Organization (ESO). For more information, visit https://www.etsi.org.